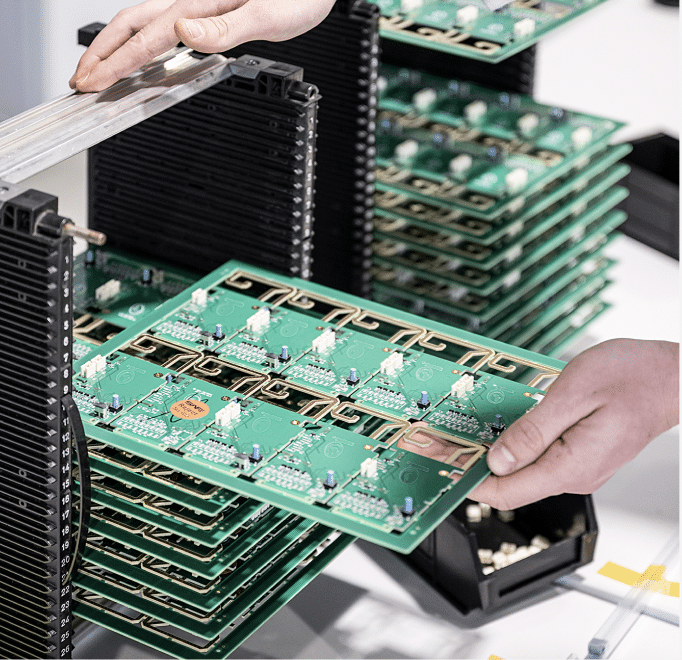

PRODUCTION OF ELECTRONIC CARDS

Since 1993, Aptem has been supporting companies that need to outsource all or part of their electronics. We work on projects of all sizes, from small to medium series, for a variety of industrial clients. Based in Annecy in the Rhône-Alpes region of France, we are committed to being reactive and delivering on time, with a commitment to quality.

We work on projects of all sizes, from prototype to small or medium series for various industrial clients. Based in Rhône-Alpes in Annecy, we provide tailor-made products 100% made in France and are committed to being responsive, delivering within the announced deadlines, while committing to the quality provided (ISO 9001)

As a subcontractor of electronic boards, we put all our know-how into electronic prototyping, printed circuit board assembly and the production of small or medium-sized series.

MACHINE PARK

Our machine park and our know-how allow us to carry out your most varied electronic projects. We master the latest technologies and are equipped to meet your specific and complex needs.

With the production of electronic cards carried out entirely in Annecy, you can be sure that you will not be subjected to the hazards of international subcontracting.

Our machine park for protyping :

– TWS laying machine

– Asscon Steam Phase Reflow – Capacity 500 X 500 m

– PDR rework machine

Our machine park for the series :

– Universal Genesis GX37D laying machine

Production capacity: 30,000 components per hour

Format 500 X 500 mm – 8 zone Heller 1707MKIII oven

– Lead-free selective wave

– Automatic screen printing machine ESE

– 3D inspection – Auto cleaning – Vibrating scraper

– Assembly station (screwing, customised fitting tools, etc.)

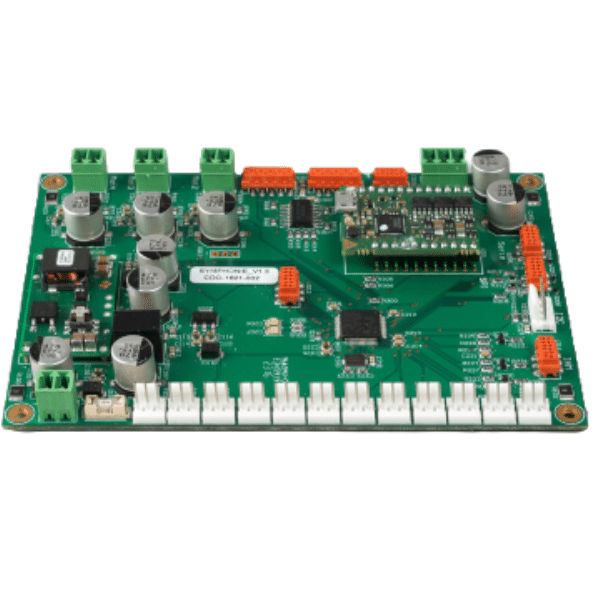

QUALITY

Our technicians master the 2 cabling processes: Through-hole and SMT (Surface Mounted Components) according to IPC 610A standards

If the so-called “through” wiring of the components provides greater longevity to the cards, the SMD solders without perforation make it possible to optimize the dimensions of the electronic card.

We have semi-automatic or automatic SMT connection machines in our workshops and also carry out SMT welding under binoculars, for greater precision in the assembly of your electronic cards.

We also acquired an optical inspection machine (AOI) to check the quality of the welds.

INDUSTRIALIZATION & PRODUCT ASSEMBLY

In addition to our electronic card wiring activities, we offer to take care of your assembly and integration operations.

Thanks to our engineers specialized in industrialization, we carry out the design and construction of the assembly line in order to optimize the assembly and testing stages of your product.

We can carry out installations and test benches depending on the specificities of the product to be assembled.

We also ensure the supply of components and elements to be integrated, whether plastic & metal parts, motors, cables, etc.

By being your single point of contact, APTEM secures your supplies while optimizing manufacturing times and costs.

Subcontracting projects carried out each year

%

Satisfied customers

Years of existence

OUR SKILLS IN ELECTRONIC CARD MANUFACTURING

SEE ALL OUR CASE STUDIES

AND PRACTICAL APPLICATIONS

Contact-us