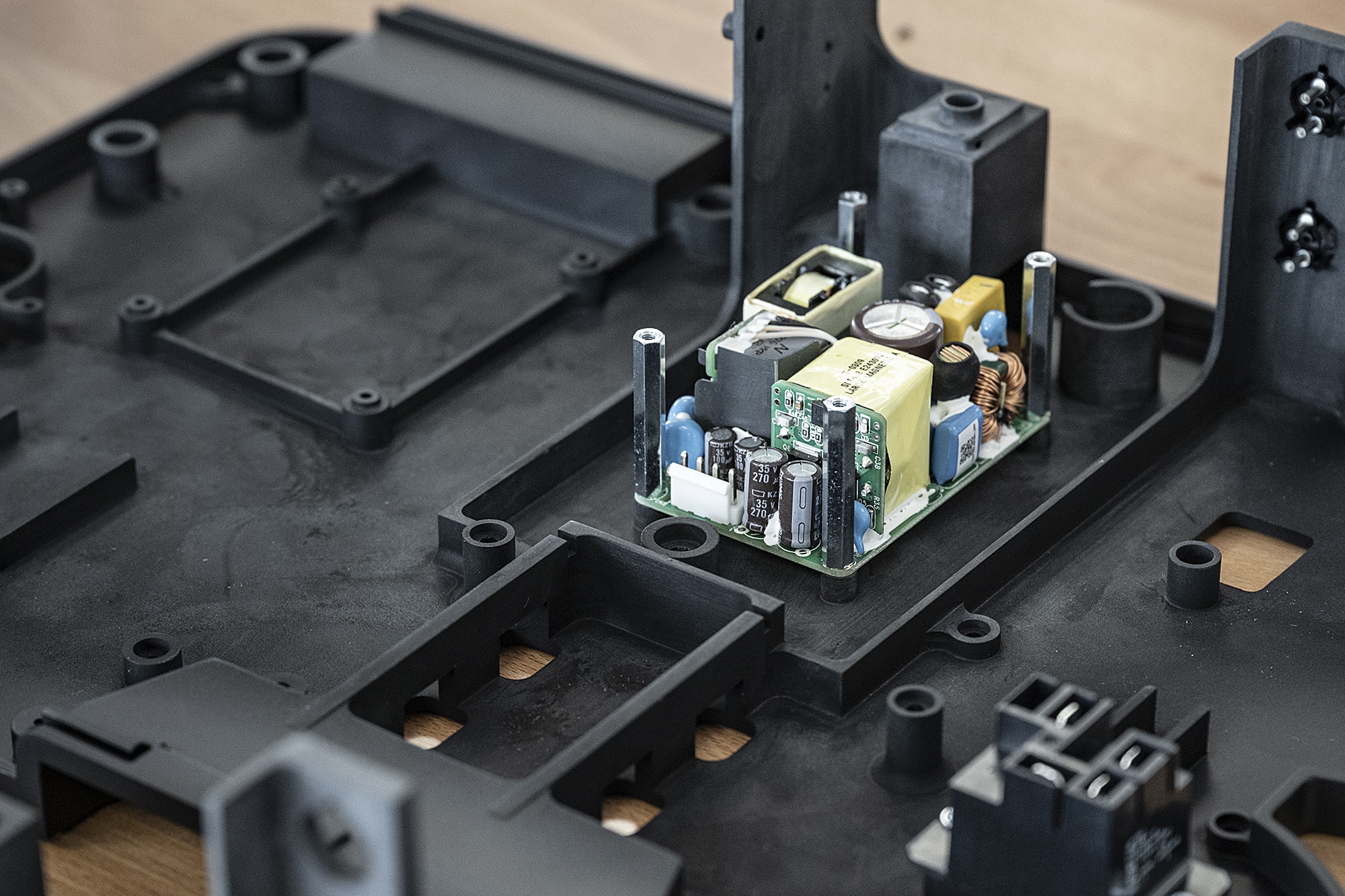

MANUFACTURE AND ASSEMBLY OF PROTOTYPES

After validation of the 3D models (mechanical and electronic), we can launch the manufacture of your prototype with our partners, for that several technologies are conceivable according to the number of specimen and the desired finish :

- 3D plastic or metal printing

- Plastic or metal machining and sheet metal work

- Vacuum duplication

- Prototype injection

3D printing

Several 3D printing processes exist:

- Powder sintering

- Stereolithography

- Wire laying

In our premises in Annecy, we have a wire deposit printer and a stereolithography printer enabling us to prototype your parts

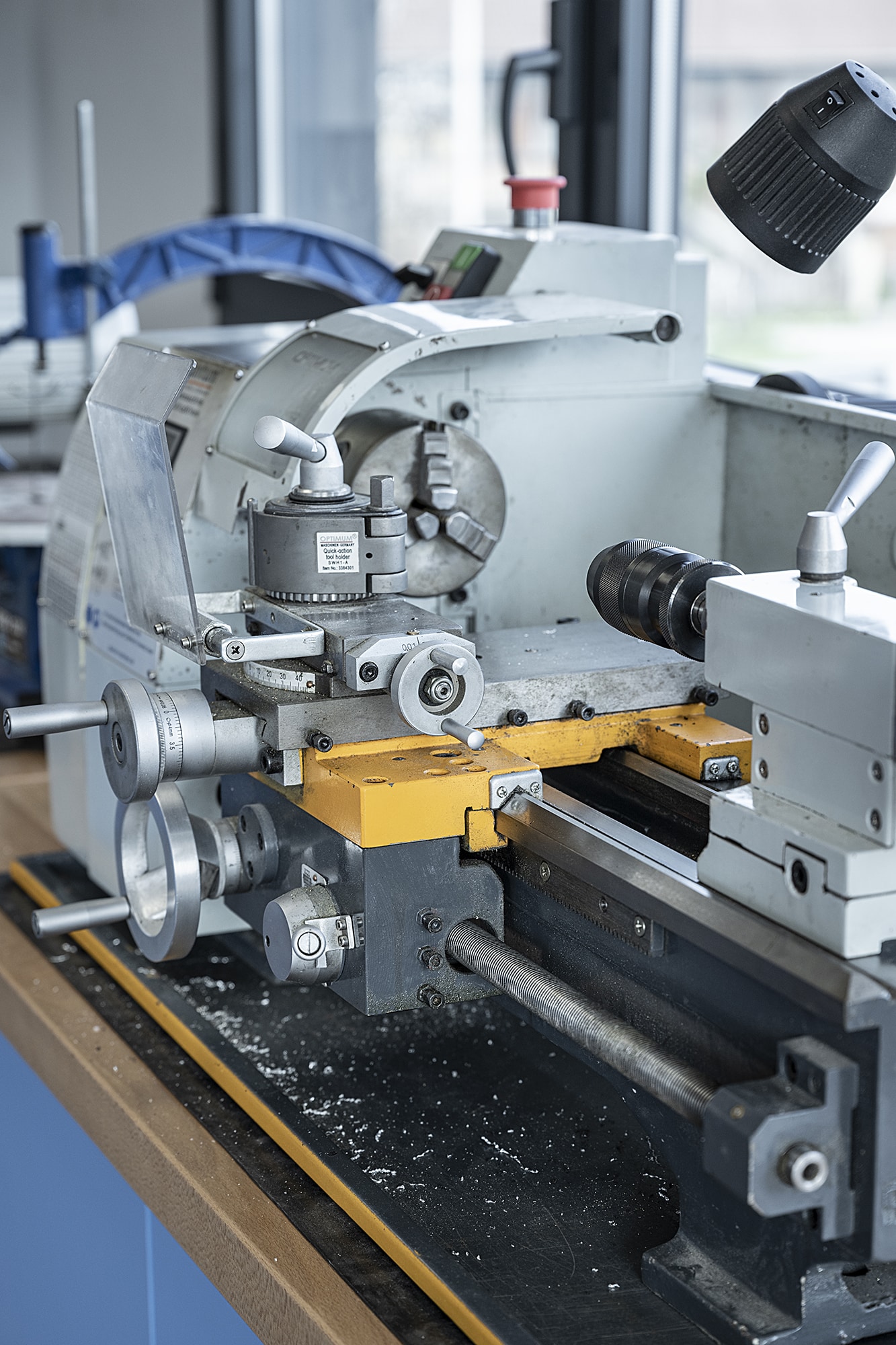

Machining and sheet metal work

Our network of partners in Haute-Savoie and in France allows us to produce all types of metal or plastic parts, painted or not, depending on the degree of finish you require.

Metal materials :

• Aluminium

• Steel / stainless steel

• ……

Plastic materials :

• Peek

• ABS

• Polypropylene

• Polyamide

• Polycarbonate

• ……

Other materials :

• Wood

• HPL

• Foam

• …….

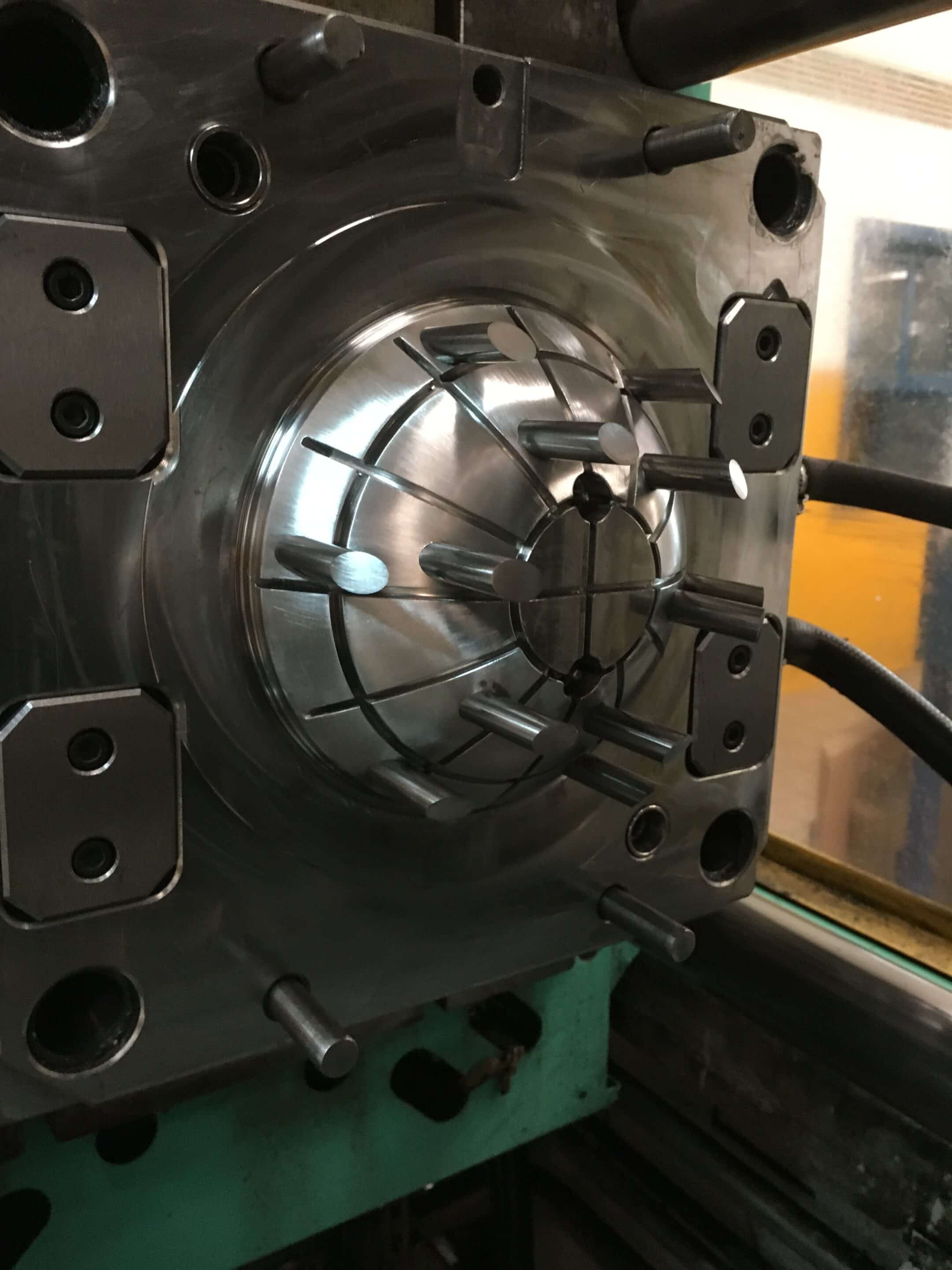

Vacuum duplication and prototype injection

Before launching “series” tools, which are often expensive, it may be interesting to start by duplicating the prototypes by 10, 20 or 50, in order to carry out trials or user tests. For this, we can offer you two economical techniques, vacuum duplication or prototype injection.

Vacuum duplication or vacuum casting is a rapid prototyping technology that allows the duplication of plastic parts from a master model.

Prototype injection moulding is similar to serial plastic injection moulding but based on an aluminium mould with standard cooling circuits and manual part ejection to reduce tooling costs.